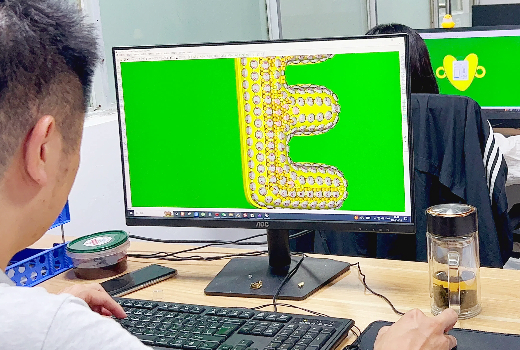

Our team of skilled 3D jewelry designers and molding engineers is ready to listen to your ideas and guide you through the entire design process. We offer expert advice on the best materials and structures to ensure both durability and aesthetic appeal. Whether you start with a simple concept or a detailed plan, we transform your custom design into a reality that perfectly aligns with your business requirements.

2. Silver Mold and Wax Building

We will invert the mold, generate a silver mold, generate a wax piece. Wax is inverted to mold to generate a silver piece.

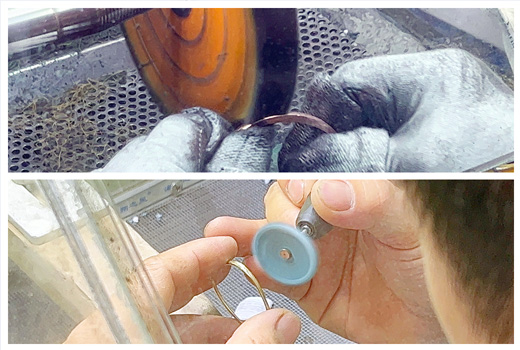

3. Stone Setting

Based on the jewelry design drawings, gemstones are carefully selected and sorted by hand to ensure they match the specified color, cut, and size, preparing them for setting.

Our seasoned artisans meticulously set each gemstone by hand. In some cases, micro-setting is necessary, a highly specialized technique that involves setting stones under magnification of up to several dozen times!

Once the jewelry has been shaped, the metal surface and intricate details require further polishing. Some pieces even undergo a second polishing process before plating to achieve a smoother finish. The polishing must be done carefully to ensure that the jewelry does not deform and that no stones are dislodged.

5. Quality Control

Joacii Jewelry aspires long term development. Especially pay attention to quality control from all aspects. We are in fine jewelry craft, and under the control by over 40 QC person, along with 2 years warranty.

6. Packing

We support customers to customize packaging bags and boxes.

7. Custom Jewelry Production at Joacii Jewelry Factory